Rigid-Flex PCB Manufacturer Comparison

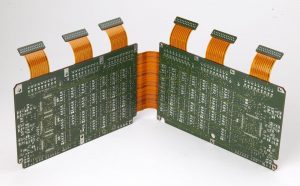

The need for more compact and densely packed electronic devices has led to the evolution of rigid-flex printed circuit boards (RFPCB). While traditional PCBs cannot meet these requirements, flex PCB technology can. In this article, we will look at the benefits of using this type of PCB.

PCBs are fabricated through a multi-step process. The first step involves drilling the holes. The manufacturer uses specialized tools for this task to ensure accuracy. This is a crucial part of the manufacturing process and requires precision. In addition, the manufacturer may use laser drilling techniques to create small and precise holes. Once the hole is drilled, copper is deposited on it. This allows for layer to layer electrical interconnections.

After that, the copper is etched to remove any unwanted metal and to expose the surface area for soldering. This is another critical step in the rigid flex pcb manufacturer. The etching process can be done in two ways: photo imaging or screen printing. The latter is more popular since it requires less labor and produces a better result.

Rigid-Flex PCB Manufacturer Comparison: Finding Your Perfect Match

The next step is to add the solder mask and silkscreen, which will cover the copper traces. These will prevent the solder from leaking and protect the traces from mechanical stress. Lastly, the manufacturer will apply a layer of protective plastic called polyimide to the top and bottom of the board. The manufacturer may also add an additional layer of protection to reduce electromagnetic interference (EMI).

While these steps are important, the most critical aspect of a flex PCB is its design. In order to avoid costly mistakes, the manufacturer must have a clear understanding of the client’s design and specifications. This will ensure that the board meets all required standards and can be produced efficiently.

A reliable rigid-flex PCB supplier will be able to provide its clients with high-quality products. They will be able to deliver boards that can withstand rigorous conditions and varying temperatures. They will also be able to reduce assembly costs by incorporating fewer connectors into the circuit.

PCBMay is a reputable company that provides a wide range of rigid-flex PCBs. The company has been in business for more than 20 years and adheres to strict industry standards. Its quality control team performs a variety of tests on the boards, including E-tests and laboratory testing.

RayMing is a rigid-flex PCB manufacturer that has advanced capabilities for fabricating high-quality rigid flex PCBs. Their streamlined production processes allow them to provide quick turnaround times. They have invested in sophisticated machinery from both home and abroad, such as LDI exposure machines and laser cutting machines. They also have a team of engineers that can produce rigid flex PCBs with great accuracy and speed.

Technotronix is a leading rigid-flex PCB supplier with extensive experience in the industry. The company specializes in the manufacture of a broad range of rigid-flex PCBs, and they offer a variety of services to suit your needs. These include design, assembly, and test services. They are a UL-certified company that adheres to strict industry standards. They are also a one-stop shop for all your PCB needs.